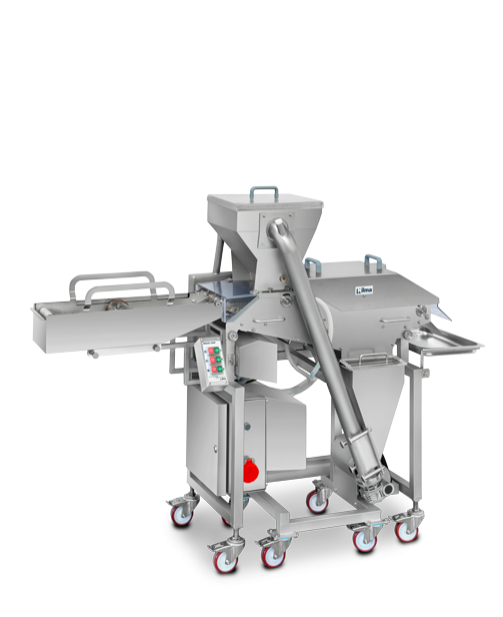

MS/4 INOX

Automatic hamburger and meatball moulding machinesHAMBURGERS AND MEATBALLS PERFECTLY FORMED

Making hundreds of hamburgers and meatballs by hand demands large amounts of labour, takes a long time and involves hygiene risks. Moulding and weight both have to be precise. All this can be accomplished by using MS/4, the Nilma automatic hamburger moulding machine, able to:

- form even, compact, uniform hamburgers and meatballs;

- ensure that each piece has exactly the required weight;

- deliver a perfect product presentation;

- provide a high output with just one worker;

- guarantee unbeatable hygiene, since there is no manual handling of food.

What’s more, MS/4’s two interchangeable shaping discs are able to produce meatballs having a diameter of 40 mm or hamburgers having a diameter of 90 mm, with an adjustable thickness up to a maximum of 22 mm.

MS/4 is rugged, since it is built in AISI 304 stainless steel, and bowl, paddles and shaping disc are easily removable and washable in a dishwasher.

MS/4 works automatically: the user simply places minced meat in the bowl and sets the thickness, obtaining the high-speed production of 1,200 hamburgers or 2,400 meatballs per hour.

Much less hassle and much more time for other tasks!

DOWNLOAD THE CATALOG

DOWNLOAD THE CATALOG

IT

IT ES

ES FR

FR DE

DE