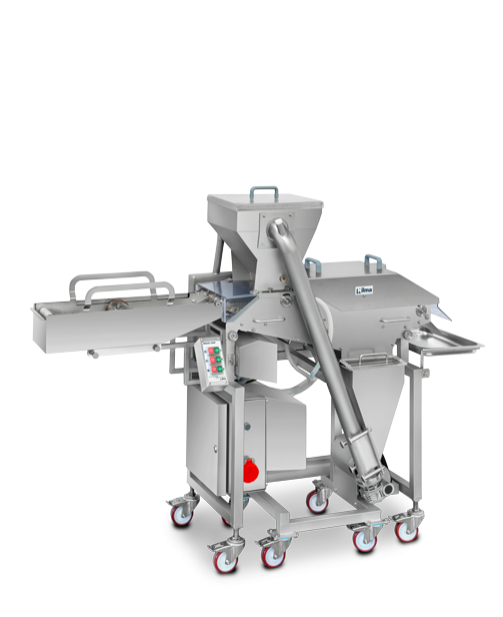

SPEEDY CUTTER DSF

HEATED VERTICAL FOOD CUTTER WITH VACUUMCOOKING AND BLENDING IN A SINGLE APPLIANCE

The DSF 40, 70 and 120 vertical cutters represent Nilma’s full range of professional heated food processors with vacuum system. Extremely versatile, they are widely used in large kitchens, food preparation centres and industrial food processing plants.

The major benefit of using the DSF Speedy Cutter is its versatility, since it performs multiple processes for both food preparation and cooking, simultaneously or in sequence, in a single appliance, with large savings in terms of time and labour.

The DSF Speedy Cutter blends, chops and homogenises, with adjustable speed, an infinite variety of products, including cheese, meat, eggs, vegetables, fruit and nuts. It mixes, amalgamates and whisks: mayonnaise, pesto, confectionery and much more. It melts, heats, cooks and chills (optional), in accordance with the Cook&Chill standards, sauces, custards, pâtés, soups, ragouts, creamed potato, béchamel sauce, cheeses and hot chocolate. Last but not least, it vacuum cooks sauces, jams and preserves in just a few minutes, maintaining unaltered the product’s organoleptic and nutritional characteristics and enhancing its colour, taste and presentation. Built in three models, entirely made of AISI 304 stainless steel, the DSF food processors have a capacity of 40, 70 or 120 litres. They are equipped with a product conveyor baffle, steam or electric heating systems, an injector to deliver steam directly onto the product, and a vacuum processing system. The thermostatic temperature control by means of a food probe guarantees excellent cooking results.

As well as automatic washing system, flowmeter and speed adjustable from 800 to 2,400 rpm, the DSF’s control panel can be equipped with a full touch screen PLC, able to communicate with the Nilma CCMP software, which executes and saves recipes, performs the appliance diagnostics and monitors the HACCP parameters.

The strong, reliable motor designed for heavy-duty operations is equipped with an automatic blade-braking system. Depending on the intended process, the stainless steel knife-group can be fitted with smooth (standard) or serrated blades, or with mixing paddles. The lid has a quick opening mechanism. The automatic bowl tilting system simplifies the product discharge.

The largest model, DSF 120, is able to produce over a tonne of product per hour. The product discharging valve in the bowl allows the product to be pumped out automatically, in order to be transferred to packaging machines.

DOWNLOAD THE CATALOG

DOWNLOAD THE CATALOG

IT

IT ES

ES FR

FR DE

DE