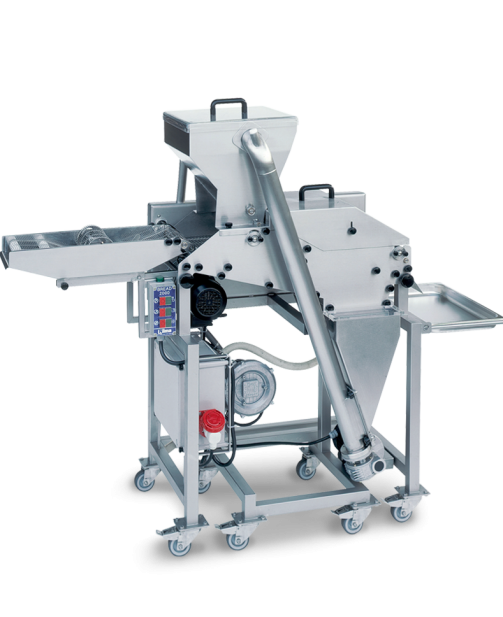

PIONEER SYSTEM

AUTOMATIC POTATO PEELING LINEA POTATO PEELING SYSTEM FOR HIGH OUTPUTS

The Pioneer Integrated System is an automatic potato peeling line that enables a high output with a minimal labour. A single unit is able to wash, peel and trim large quantities of potatoes in the most rational and economical way, effortlessly and without pauses or transfers. The processing cycle starts in the load hopper, where potatoes are collected and loaded by an elevator into one (one-way line) or two (two-way line) automatic potato peelers. After peeling, potatoes are automatically discharged into the well of the sorting table where they can be trimmed by hand. During this operation, the processed potatoes are transferred to the collection trolley by an inclined chute (one-way line) or a conveyor belt (two-way line). An RG/400 vegetable preparation machine can be installed instead of the collection trolley, to create an automatic peeling and cutting line.

The one-way Pioneer Integrated System has a capacity of 600 kg/hour of finished product, doubled in the two-way system to 1,200 kg/hour. The peeling process is controlled on the control panel by two timers which regulate the potato loading and peeling time. Pioneer System is safe because it is fitted with safety devices, and easy to clean, as the large hopper is easily inspected and the cleaning discs are removable.

Pioneer System, the automatic potato peeling system that enables large outputs and major savings, an essential aid for modern hospital and canteen kitchens, industrial food production plants and Fourth-range vegetable processors.

DOWNLOAD THE CATALOG

DOWNLOAD THE CATALOG

IT

IT ES

ES FR

FR DE

DE